- General Information

- Roto Grind Usage

Roto Grind – construction

As regards the principle of operation, the Roto Grind corresponds to a hammer grinder that is embedded on the bottom of the tub and does not contain sieve.

The material should be loaded into a slowly rotating tub with a loader of sufficient capacity, where the grinding part performs shredding and blowing.

The rotor receives the motion directly from the power machine (tractor or electrical motor). The drive chain does not include gears, which makes it extremely easy and simplifies maintenance.

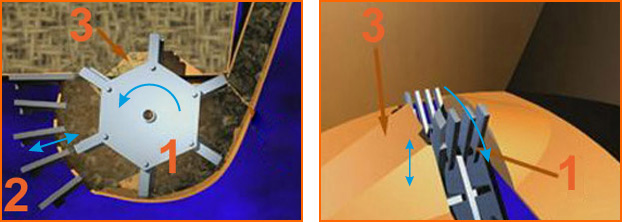

1 - Rotor with hammers; 2 - Counter knives/plates (5 pcs); 3 - Adjustable shear plates

Simple setting

The setting is done at three points:

- The rotation speed of the tub can be controlled by hydraulics.

- The length of the chopped material can be adjusted by the counter knives (plates).

- The grinding capacity (t/h) depends on the power engine and can be controlled by means of a shear plates up and down on the inside of the tub. (Depending on the position of the shear plates, how much hammers can stretch into the material to be cut, so how much can they break off at the same time.)

Machine variants, standard equipment

Trailer Type Roto Grind |

Stationary type Roto Grind |

|

|

The stationary type Roto Grind tub grinders are manufactured only on special orders! |

Options

1. Heavy weight hammer 6×1 pcs (standard); 2. Adapter for grinding corn seed; 3 Light weight hammers (6×4 pcs) for fine grinding